Our Technical Resources Technical ResourcesTechnical Resources

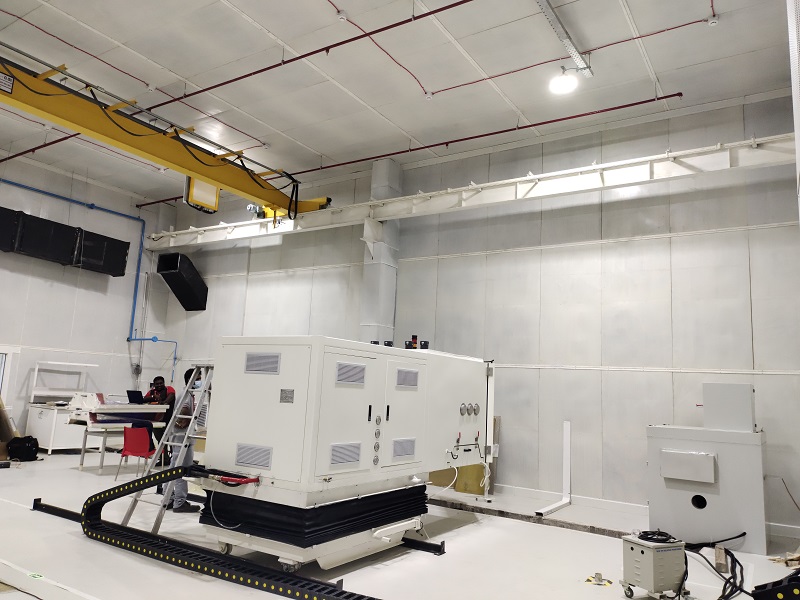

The company has the most modern fabrication machinery and equipment along with highly experienced fabrication teams. Regular training and development programs, up-gradation to new fabrication systems and continuous emphasis on high safety standards at work place, ensure a motivated and skilled workforce.

{"slidestoshow":3,"slidestoscroll":1,"dots":"false","arrows":"true","autoplay":"true","autoplay_interval":3000,"speed":300,"loop":"true","lazyload":""}

| Description of Machninery | Capacity |

|---|---|

| Hydraulic Shearing | 4100mx6mm |

| Hydraulic Press Break | 4100x125tons |

| Mechanical Power press | 40 tons |

| Plate bending machine | 2000x20mm |

| Profile gas cutting machines | 8'x4'x20mm plates |

| TIG Welding | 230 amps |

| MIG Welding | 400 amps |

| Welding machines | - |

| Auto-CAD (Designing & Drafting) | - |

| Spray Painting facility | - |

| Pillar Drilling machine | 40 & 25 mm |

| Magnetic base core drilling | 40mm dia. |

| Radial drilling machine | - |

| Lifting tools | 5, 2 & 1tons each |

| Area & Manpower | Size |

| Covered shed area | 2910sq.ft |

| Open area | 32290sq.ft |

| Production Capacity | 20tons/month |

| Skilled Workers (Fabricator, Fitter & Welder) | 6 Nos. |

| Semi-Skilled Workers (Grinder & Kalasi) | 4 Nos. |

| Helpers | 6 Nos |

| Sr. Foreman, Engineers | 4 Nos. |

Challenges keeping in tune with the company’s motto ‘Quality work’

We have developed a specialized team to plan and execute Project and maintenance of process plants and have successfully executed such projects in time and with short mobilization notice.